What Is Torque Vectoring ?

Cars run on a variety of tracks, which can change from time to time. Cars are frequently required to undertake a variety of unexpected turns for which the mechanical automobile system must be prepared. Torque vectoring is a complicated topic that affects how a vehicle turns. The clutch is an important component that affects how torque is applied to a vehicle. The physics is unquestionably interesting to examine, given how crucial it is to a car’s operation.

What Is Torque Vectoring and How Does It Work?

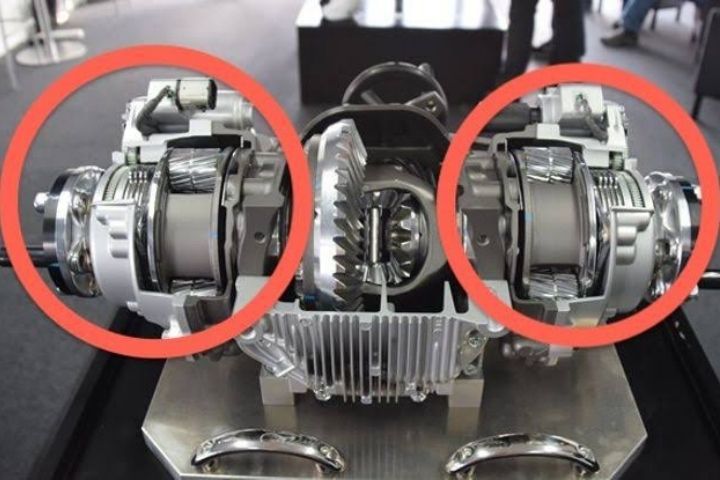

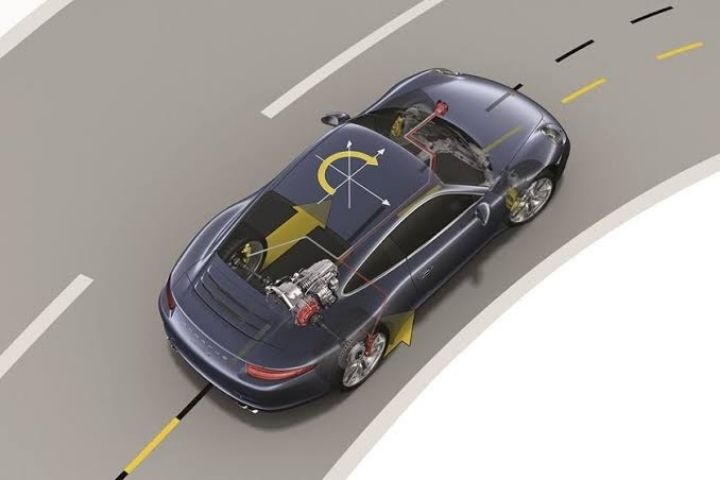

The distribution of torque between the wheels is referred to as torque vectoring. Automobiles employ this process to alter the torque at each half-shaft. Torque vectoring is based on the concept of a differential for the wheels. On the axle, one wheel might go faster than the other. For greater efficiency and precision, this idea is usually regulated electronically.

The clutch pack that controls torque vectoring is in an open differential state when the car is travelling in a straight line. This indicates that the torque is evenly distributed over both axle wheels. To maintain grip in a hairpin bend, the torque is transferred to the outer wheel. If another abrupt turn occurs, the torque is transmitted to the wheel with the most grip once more. The torque is redistributed to the outer rear tyre to minimise understeering while accelerating out of turn, and the turning is smooth.

Types Of Torque Vectoring

- Brake-based torque vectoring

Systems that rely on brakes are more reliable and efficient. Instead of relying on a differential system, one of the axle’s wheels is stopped. This provides a momentary differential, which allows the wheel to turn smoothly.

- Electric-based torque vectoring

Each wheel in this arrangement is equipped with an electric motor. As a result, each turn is managed independently. The installation of a regenerative braking system allows for a continual shift in torque, causing the vehicle to turn.

Torque Vectoring Pros

One of the most significant advantages is the car’s ability to turn smoothly when passing around hairpin turns. The steering lock and understeering are both successfully decreased, making turning more accessible and efficient. Torque vectoring improves the safety of driving. Going through various turns does not require the car to spend energy unnecessarily. Torque vectoring decreases the likelihood of any mishaps, which might be disastrous. Individual wheel control is possible using torque vectoring. This means that the wheels don’t have to be controlled by a single system, and the power and torque levels can be altered independently to make driving more enjoyable.

- Also Read :

- Explained : 3 Cylinder Vs 4 Cylinder Engine | Difference, Pros…

- First Diesel Engine : Unfolding it’s History

- Top 10 Most Powerful Production Cars of The Last Decade

Join Us: Facebook | Whatsapp | Instagram