Various Transmission System in Cars Explained

Transmission mostly termed as gearbox are most important part of an automobile. The power genrated by the engine needs to be transmitted to the wheels. This can be achieved with help of mechanical parts which collectively form a system. This system is termed as transmission.

Now a days automakers development more advanced gearbox for there cars the basic working elements same. And the working and design are notably identical to each other. This blog is all about the basic design and working of gearboxes. So let’s get straight into it.

Also Read: Explained : 3 Cylinder Vs 4 Cylinder Engine | Difference, Pros…

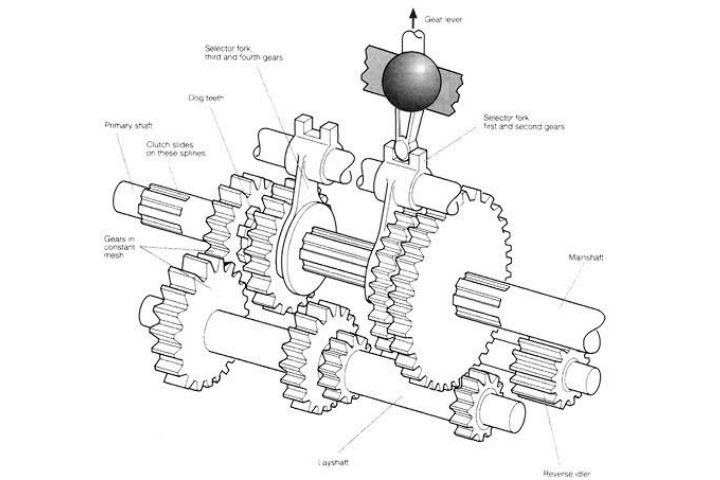

1. Sliding Mesh Gearbox

The most simple type of transmission or gearbox is absolutely the Sliding Mesh Gearbox. In this type, the gears on the layshaft are fixed to the shaft rigidly, whereas the gears on the main shaft can slide on it. The fork of the gear stick slides the main shaft through the specific gear. And the desired gear ratios are thus selected.

It is the oldest type of gearbox used in early models by car makers. Some of them are –

Alfa 12HP used a sliding mesh gearbox with 4 -speed manual transmission.

Mercedes 35HP used 4-speed manual transmission

Also Read : The Los Santos Tuners Update Adds A Host of New Cars to GTA Online

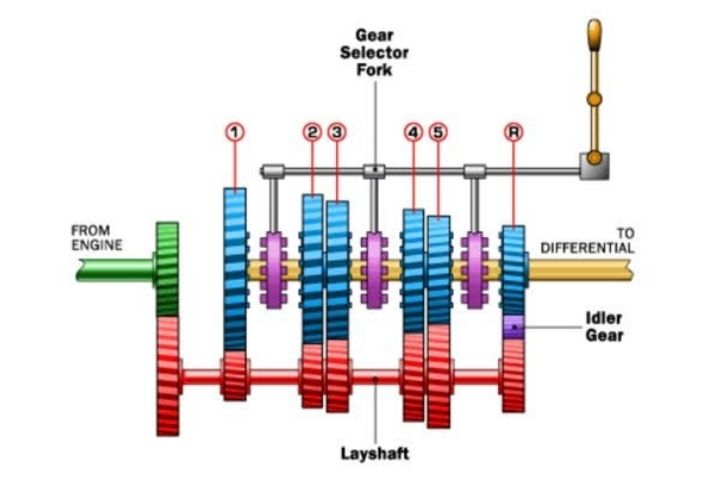

2. Constant Mesh Gearbox

This type of gearbox slightly differ from the sliding mesh gearbox. In Constant mesh transmission is a type of gearbox in which all or most of the gears are always in mesh with one another. In a constant-mesh manual gearbox, Gear ratios are selected by dog clutches that connect the various gear sets to their shafts so that power is transmitted through them. When you shift gears the fork slides the dog clutch to engage to the specific gear ratio. Two or more dog clutches can be used with respect to the no the gear sets.

The constant-mesh gearbox was dominantly used in farm trucks, motorbikes and heavy machinery. Notably, it was also used in the Ford Model T.

Also Read : Cruise Control – Is It Essential?

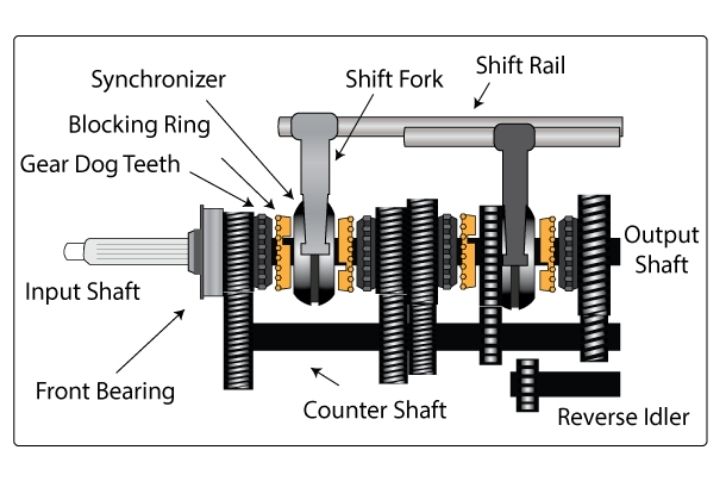

3. Synchromesh Gearbox

Synchromesh Gearbox is an improved version of Constant Mesh Gearbox. Here the dog clutch of Constant Mesh Gearbox are replaced with special gears. The synchroniser cone is used for smooth and quick transmission. The conical grooves cut over the gear provides frictional contact to the gears which is to be meshed in order to equalise the speed of the moving shafts.

It is now the widely used gearbox. It is used in bikes like ktm duke 390cc. Also most of the race cars like formula-1 also uses them. It’s application is widely is in passenger vehicles.

Also Read : 6 Simple Ways To Increase Mileage Upto 10 Percent

Comparing Gearbox: Pros and Cons

| Sr. No | Type of Transmission | Sr. No. | Advantages | Disadvantages |

|---|---|---|---|---|

| 1. | Sliding Mesh Type | a) | It has Simple mechanism | More effort is required to shift gears |

| b) | More efficient as compared to Constant Mesh Gearbox | More wear and tear of gears due to friction | ||

| c) | Easy to manufacture | Difficult to maintain and repair | ||

| 2. | Constant Mesh Type | a) | Compartively quiter operation | Less efficient compared yo other types of gearbox |

| b) | Any vibration or harm is only caused to the dog clutch. Making it easy to repair | The double clutch mesh is required. | ||

| 3. | Synchromesh Type | a) | Smooth and noise free gearshifts | High manufacturing cost |

| b) | Low risk of gear damage in quick shifts | Can not handle high loads |

- Also Read :

Join Us: Facebook | Whatsapp | Instagram