A Short Guide To Four-Stroke Engine | Internal Combustion Engines Explained

Introduction To Engine

Engines are one of the most fascinating mechanical systems in todays world. From motorcycles and cars to lawn mowers and generators, engines provide power to a variety of different kinds of equipment. Whether you’re currently working in the field or are considering becoming a technician, it’s important to understand exactly how a engine works. However, different types of engines are available in the market.

These are further classified based on working, size, construction and a lot more aspects. Differentiating engines on the basis of working, there are two basic types, two-stroke and four-stroke engine. This blog will provide you everything you need to know about four-stroke engine.

Read More: 3 Cylinder Vs 4 Cylinder Engine | Difference, Pros

Four-Stroke Engine And It’s Working

A four-stroke or four-cycle engine is an internal combustion (IC) engine in which the piston completes four separate strokes with crankshaft completing two revolutions. A stroke refers to the full travel of the piston along the cylinder, in both upward and downward direction. this type of engine uses four types of distinct piston strokes to work efficiently. The four separate strokes are termed as:

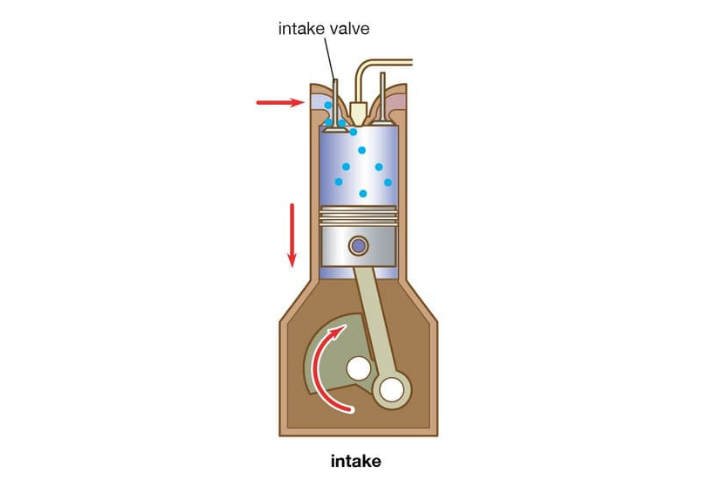

1. Intake Stroke

The intake stroke also known as induction or suction stroke begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). During this stroke the intake valve must be in the open position while the piston allows an air-fuel mixture into the cylinder. This happens due to vacuum pressure produced into the cylinder because of the piston’s downward motion. The piston is moving down as air is being sucked in by the downward motion against the piston.

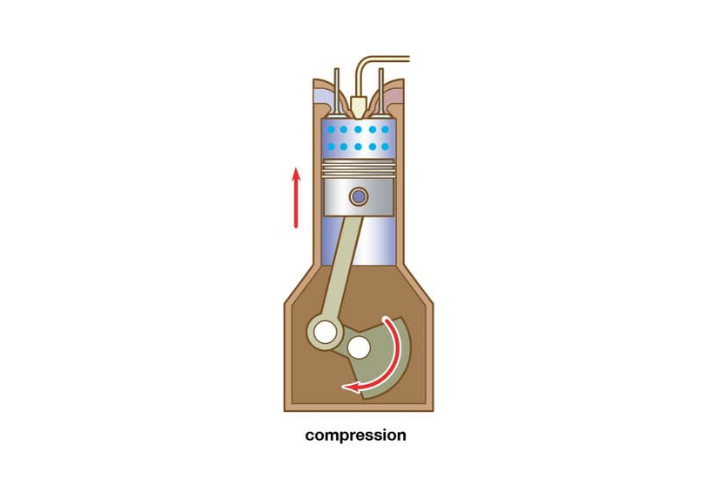

2. Compression Stroke

The compression stroke begins at bottom dead center (B.D.C) or just at the end of the suction stroke, and ends at top dead center (T.D.C). Both the intake and exhaust valves are closed during this stage. Further, during this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke.

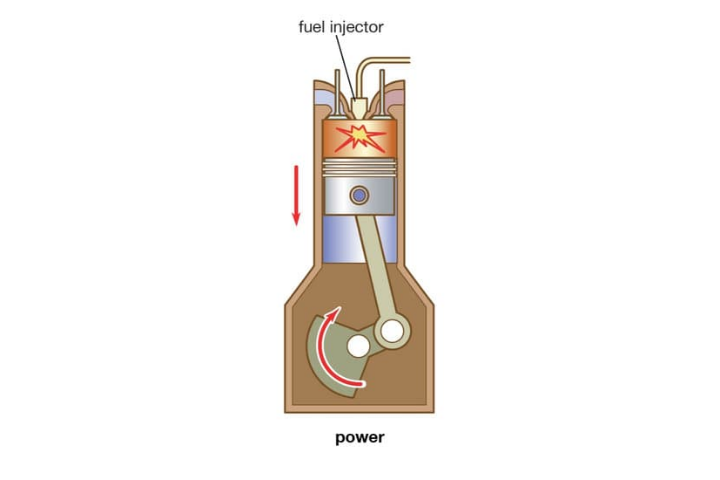

3. Combustion Stroke

This is the stroke where the power is generated and is also known as power or ignition stroke. Furthermore, this stroke is the start of the second revolution of the four stroke cycle. At this point the crankshaft has completed a full 360 degree revolution. While the piston is at the top dead center (T.D.C) which is the end of the compression stroke, the compressed air-fuel mixture is ignited. This ignition is carried out by a spark plug in a gasoline engine or by heat generated by high compression in diesel engines, further, forcefully returning the piston to bottom dead center (B.D.C). This stroke produces mechanical work from the engine to turn the crankshaft.

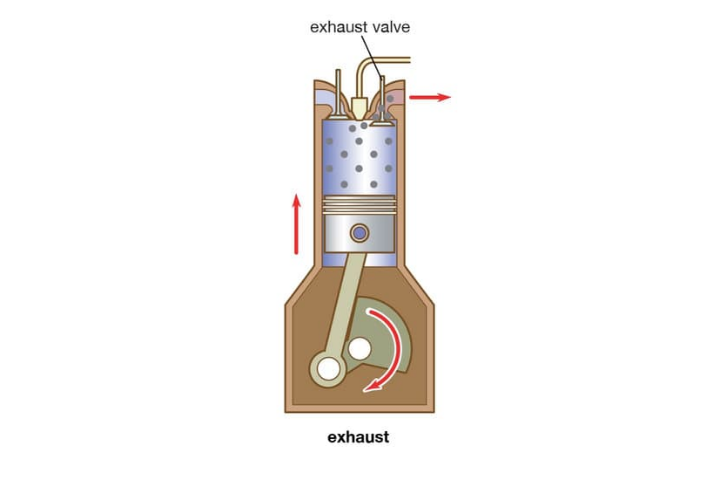

4. Exhaust Stroke

The Exhaust stroke is also known as outlet stroke. During the exhaust stroke, the piston, once again, returns from bottom dead center (B.D.C) to top dead center (T.D.C). During this stroke, the exhaust valve is open. This stroke drives out the used air-fuel mixture or any waste produced during power generation through the exhaust valve.

Parts Of A Four-Stroke Engine :

- Piston

- Crankshaft

- Camshaft

- Spark plug

- Cylinder

- Valves

- Carburetor

- Flywheel

- Connecting rod

- Fuel injectors

Advantages

- Four-stroke engines deliver a good balance of power due to more number of rotations in the engine. Also they comparatively more reliable and efficient.

- These engines separate each event mechanically, which reduces unburned fuel emissions.

- For-strokes also separates oil from fuel, which significantly reduces carbon monoxide emissions.

- Less wear and tear due to good lubrication system.

- These re quieter in operation as they idle smoothly and due to the valves present on the cylinder.

- The four-stroke engine give high torque at low rpm.

Dis-Advantages

- Less power is generated as it gets delivered once every 2 rotations of crankshaft.

- The number of parts and various inputs like cooling, lubrication, valves, design makes it very complicated to design and even more challenging to construct.

- The more number of parts included makes it costly compared to simpler designs.

Application

- Four stroke engine are widely used in automobile industries.

- They are used in bus, trucks and other transportation vehicles.

- They are used in pumping systems.

- These engines can also be seen used in mobile electric generators.

- Four-Stroke engines are also used in aircraft and marine engines.

- Four-Stroke diesel engines find application in pump sets, construction machinery, air compressor, drilling rigs, etc.

Also Read :

- Indian Automobile Industry | 10 Less Known Facts About It

- Top-selling sedans in the US in 2021

- Why Mahindra is popular in India ?