Different Types Of Clutches Used In Automobiles | Short Guide On Clutches | Function OF Clutch

What is Clutch?

Clutch is a device which is used to transmit power from one shaft to another. It connects a shaft on which it is mounted to another shaft which is in motion. Clutches are generally used in automobile to transmit power from engine to the driving wheels. In cars it transmits power from the flywheel connected to the engine shaft to the clutch shaft, and from clutch shaft it is transmitted to the rear wheels through gear shaft, propeller shaft and differential.

Requirements of a Good Clutch –

- Gradual Engagement

The clutches should engage each other gradually and positively in order to prevent the sudden jerks produced.

- Size:

The size of the clutch should be small as possible, so that it can be fit into minimum space. The smallers the clutches are, the lesser area it will occupy.

- Torque Transmission

The clutch should be so designed, so that it can able to transfer maximum power through it. However, it depends on factors like total area of friction surface, friction coefficient, normal force acting on clutch and heat dissipation respectively.

- Heat Dissipation

Thermal capacity is the ability of a given clutch or brake to absorb and dissipate heat without reaching temperatures that would harm the operation. Therefore, it must be designed accordingly, so that maximum dissipation of heat takes place from it.

- Dynamic Balancing

Basically, all machines have some form of residual vibration. Enormous vibration in rotating machinery can cause high levels of noise and more importantly. Dynamic balancing is a way of balancing machines by rotating parts quickly. Therefore, for high speed clutches dynamic balancing is necessary.

- Provision of Clutch Free Pedal

The clutch pedal should go downward three-quarters of an inch to 1 inch without effort and then requires more effort to travel the rest of the way down to the floor, this is called as pedal free-play. This pedal free-play ensures that when you release the pedal, the clutch disk is fully engaged. Hence, there should be a clutch free pedal in engaging or disengaging of clutch.

- Ease of Operation

Whether it be any application, the basic function of a clutch is to transmit torque from a rotating driving motor to a transmission. In a vehicle, it must offer an smooth operation of engagement and disengagement for the driver and should not be difficult or tiresome to the operator.

- Vibration Damping

Due to high torque excitations generated in the clutch it engages unevenly, placing an unbalanced load on the clutch and flywheel surfaces further causing the vibration & noise. The vibration usually comes from the clutch disc intermittently losing its grip on the flywheel. Hence, the clutch should be designed in a way that the noise or vibration produced in the transmission can be eliminated easily.

Some Types of clutches

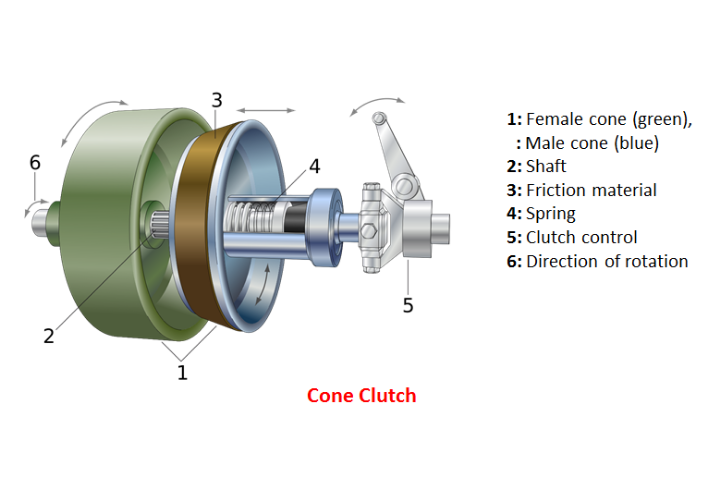

1. Cone clutch

A cone clutch serves the same purpose as a disk or plate clutch. However, instead of mating two spinning disks, the cone clutch uses two conical surfaces to transmit torque by friction.

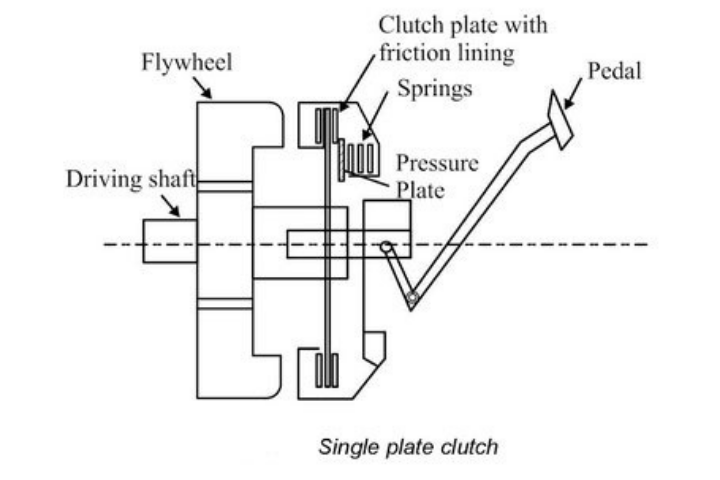

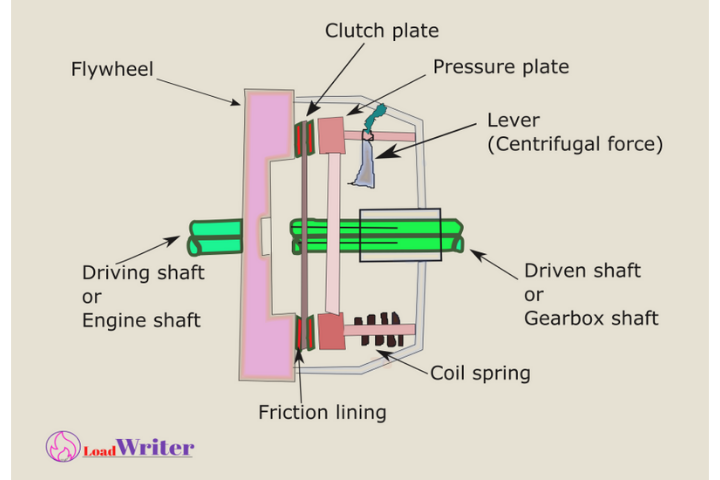

2. Single plate clutch

The Single plate clutch is the most common type of clutch plate used in automobiles. However, it consists of only one clutch plate which is mounted on the splines of the clutch plate. Further, the Flywheel is mounted on the engine crankshaft and rotates with it.

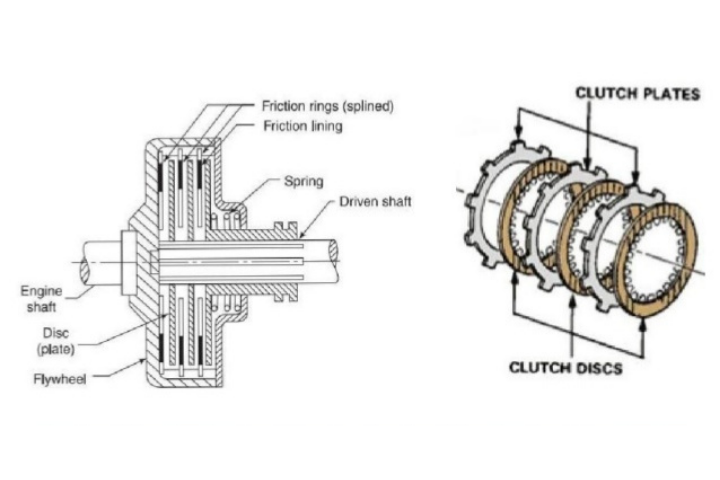

3. Multi-plate cutch

As it is named, the multi plate clutch uses multiple clutch plates to transfer power between the engine shaft and the transmission shaft. Further, these types of clutches are used in heavy vehicles with racing cars and motorcycles for transmitting high torque.

4. Semi-centrifugal clutch

Semi Centrifugal Clutches use less stiff clutch springs as they operate only at low engine speeds. Hence, they are used in high powered engines and racing car engines where clutch disengagements require appreciable and tiresome drivers effort.

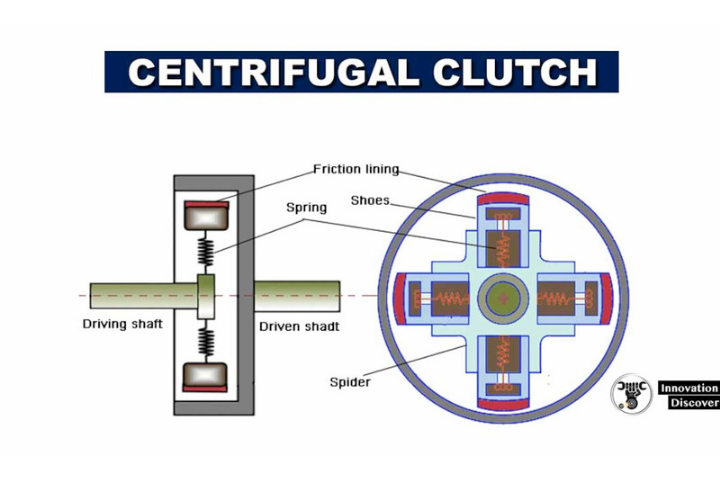

5. Centrifugal clutch

A centrifugal clutch is an automatic clutch that uses centrifugal force to operate. However, the output shaft is disengaged at low rotational speed and engages more as the speed of engine increases. Furthermore, it is used in mopeds, underbones, lawn mowers, go-karts, chainsaws and mini bikes.

The main parts of a clutch are mainly divided into three groups-

1. Driving Members

The driving members consists of a flywheel which is mounted on the engine crankshaft The flywheel is bolted to a cover which carries pressure plate, pressure springs and releasing levers. However, as the flywheel is bolted to the cover assembly, the entire assembly of the flywheel and the cover rotate all the time. The clutch housing and cover provided with openings so that the heat produced during the function dissipates easily.

2. Driven Members

The driven members consists of a disc or plate also called as clutch plate. The clutch is free to slide on the splines of the clutch shaft. It carries friction materials on both of its surfaces. When the clutch plate is gripped between the flywheel and the pressure plate, it rotates the clutch shaft through splines.

3. Operating Members:

The operating members consists of a foot pedal, linkage, release or throw out bearings and are in hand of the operator or the driver of the automobile.

- Join Our Community:

- Telegram Group:- Click Here

- Facebook Group: Click Here

- Facebook Page: Click Here

- Whatsapp Group:- Click Here

- Instagram:- Click Here

- Also Read :

- The Greatest Car World Records | Insane Car World Records

- Chinese Copycat Cars | Top 10 Cloned Chinese Cars

- Used Luxury Car Vs Brand New Car Which One Should You Buy